- Sales SupportContact Sales

- Call us at: +(86) 15211074652

- Send us a email at: info@zr-fibercable.com

Optical fiber fusion splicer configuration, connection method and operation steps

The optical fiber connection adopts the fusion splicing method. Welding is based on melting the inner hole of the optical fiber and connecting the two optical fibers together. The whole process is similar to the welding of metal wires, and it is generally carried out by electric isolation.

1. Basic knowledge of optical cable

OPTIC FIBER is made of pure calcite (laminated glass) with a special processing technology into a glass test tube with a substance in the middle, which can transmit a large amount of information in a very short time.

1. Multimode fiber and multimode fiber

Multimode fiber

Definition: Fibers with a large core diameter (50 or 62.5μm) that can be transmitted in different relative paths (several ways).

Advantages: It is very easy to couple with the light source and other optical fibers, the light source (transmitter) is low-cost, and it has the characteristics of simple connection and fusion.

Defects: It has relatively high attenuation coefficient and low network bandwidth, which makes the transmission of light in multimode fiber limited to short-circuit lines. Application: It is mainly used in short-circuit places such as access network and local area network.

Multimode fiber

Definition: The core diameter is small (9um), and there is only one optical fiber that is transmitted by a relative transmission path (individual mode).

Advantages: clear mode dispersion, small attenuation coefficient, long-distance transmission, large network bandwidth, and can bear 10Gbit/s and 40Gbit/s data signals over long distances.

Disadvantage: It cannot be coupled with the light source and other optical fibers, and the cost of the light source (transmitter) increases.

Application: It is mainly used in remote IoT platforms, metropolitan area networks, access networks and other places.

2. General optical cable structure

The optical cable shall be constructed with one or more optical fibers or optical fiber bundles in accordance with the characteristics of organic chemistry, mechanical equipment and natural environment. No matter what kind of structure, most of the optical cables are composed of three parts: the cable core, the lifting components and the sheath.

3. Types of fiber optic connectors

The color of the outer grommet of the cable in the multimode room is generally light yellow.

The color of the outer grommet of the inner cable in the multimode room is generally orange.

4. Common fiber optic machine equipment interface mode

The optical fiber connection adopts the fusion splicing method. Welding is based on melting the inner hole of the optical fiber and connecting the two optical fibers together. This whole process is similar to the welding of metal wires, and it is generally carried out by electric isolation:

1. Optical fiber fusion equipment and special tools

2. The whole process and process of fiber fusion splicing:

(1) Strip the optical cable and fix the optical cable into the splice box

Before stripping the optical cable, part of the damage and deformation during construction should be removed, and a special stripping tool should be used to strip the outer sheath of the optical cable with a length of about 1m. Pinch the stainless steel wire that protects the cable in the grommet, use the stainless steel wire cable outer grommet to peel off, and fix the optical cable into the splice box. After scrubbing the grease clean with a handkerchief, put it into the splice box. When fixing the stainless steel wire, it must be clamped tightly, and there must be no loosening. Otherwise, it will cause the fiber optic cable to roll over and break the core.

(2) Fiber split

Pass the fibers individually over the PVC heat shrink. Separate the optical fibers of different bundles and colors and pass them over the PVC heat-shrinkable tube. The optical fiber with the coating layer stripped is very sensitive, and PVC heat-shrinkable sleeves are used to maintain the fiber optic splices.

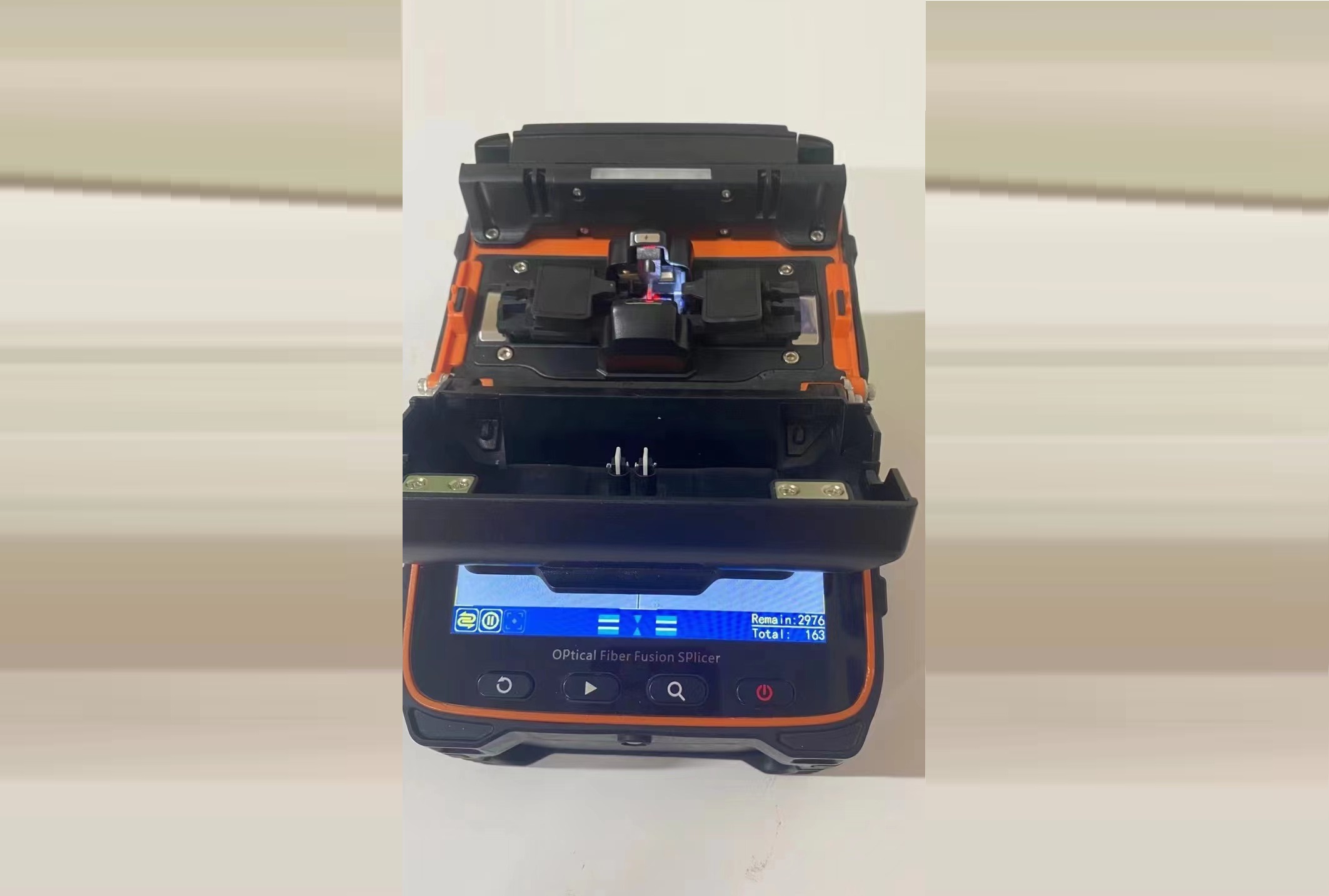

(3) Prepare the fusion splicer in advance

Turn on the power switch of the fusion splicer, use the preset program to carry out fusion splicing, and immediately remove the dust in the fusion splicer after use, especially the tooling fixture, the smoke and fiber debris of the mirror glass and V-shaped groove body.

(4) Making the inner hole for connecting the optical fiber

The quality of the inner hole of the optical fiber will immediately affect the transmission quality after the optical fiber is connected. Therefore, the inner hole of the fiber to be welded must be well prepared before welding. First, strip the coating layer on the optical fiber core with the special fiber stripper equipped with the optical fiber fusion splicer, and then replace the cleaning cotton dipped in ethanol and scrub the bare fiber several times with appropriate force.

Then use a high-precision fiber cutter to laser cut the fiber, and the laser cutting length is generally 10mm~15mm.

(5) Place the optical fiber

Put the optical fiber into the V-shaped groove of the fusion splicer, carefully press the optical fiber pin and the optical fiber fixture, and set the position of the optical fiber in the pin according to the length of the fiber laser cutting. Generally, the laser cutting surface of the connected fiber is close to the electric top level. Close the windproof cover and press the "SET" button to automatically weld.

(6) Remove the fiber and heat the PVC heat shrinkable sleeve with a heat treatment furnace

Open the windproof cover, remove the optical fiber from the fusion splicer, put the PVC heat-shrinkable sleeve in the middle of the bare fiber, and heat it in the heat treatment furnace. The electric heater can use 20mm small heat shrinkable sleeve and 40mm and 60mm general heat shrinkable sleeve, 20mm PVC heat shrinkable sleeve takes 40 seconds, 60mm PVC heat shrinkable sleeve takes 85 seconds.

(7) The fiber coil is fixed

Coil the continuous fiber into the fiber storage tray. When coiling the fiber, the larger the semi-longitude of the coil, the greater the inclination, and the smaller the loss of the entire route. Therefore, it is necessary to maintain a certain semi-longitude, so that when the laser is transmitted in the optical fiber, it can prevent some unnecessary losses.

(8) Sealing and offline

If welding in the suburbs, the splice box must be well sealed to avoid water leakage. After the fusion splicing box leaks, because the optical fiber and the optical fiber fusion splicing point are soaked in water for a long time, a part of the optical fiber attenuation coefficient will increase first. It is best to make a good moisture-proof measure for the splice box and use a hook and hang it on the pull wire. At this point, the optical fiber fusion splicing is performed.

3. Optical cable continuation quality inspection

In the whole process of fusion splicing, to ensure the fusion quality of the optical fiber, reduce the additional loss caused by the coiled fiber and the damage caused by the sealing box to the optical fiber, it is absolutely not possible to distinguish the advantages and disadvantages only by the naked eye:

1) In the whole process of fusion splicing, real-time tracking and testing of each core fiber is carried out to check the quality of each fusion splicing point;

2) After each coiled fiber, carry out a routine inspection of the coiled fiber to clarify the additional loss caused by the coiled fiber;

3) Before sealing the splicing box, carry out unified measurement on all optical fibers to check whether there is any missed measurement and whether the optical fiber and the connector are extruded in the pre-buried indoor space of the optical fiber;

4) After sealing the box, carry out final inspection on all optical fibers to check whether the sealing box is harmful to the optical fiber.

4. The key factors affecting the loss of optical fiber fusion splicing

There are many factors that affect the loss of fiber fusion, which can be roughly divided into two categories: intrinsic fiber elements and extrinsic elements.

The intrinsic elements of the fiber refer to the elements of the fiber itself. There are four key points:

1) The fiber mode field diameter is inconsistent;

2) The core diameters of the two optical fibers are mismatched;

3) The cross section of the core is not round;

4) The coaxiality between the core and the insulating layer is not good.

The extrinsic factor that affects the continuation loss of the fiber is the continuation technology. 1) Pivot shift: The multimode fiber core is thin, and the pivot shift of the two connecting fibers will affect the continuation loss.

2) Pivot skew: When the optical fiber cross section is skewed by 1°, it will cause about 0.6dB of continuous loss. If the specified continuous loss is less than or equal to 0.1dB, the tilt angle of the multimode fiber should be less than or equal to 0.3°.

3) The inner hole is separated: the connection of the RF connector of the theme activity is not very good, and it is very easy to cause the inner hole to be separated, resulting in a lot of connection loss.

4) Inner hole quality: When the flatness of the inner hole of the optical fiber is poor, it will also cause loss and even bubbles.

5) Physical deformation of the optical fiber around the continuation point: the tensile deformation of the optical cable in the whole process of construction, the high pressure of clamping the optical cable in the splice box, etc., all have an impact on the continuation loss, and even several times of welding can not be improved.

Influence of other elements:

Continuation of the actual operation level of the staff, the operation process, the technical level of the fiber coil, the cleaning level of the electric level in the fusion splicer, the basic parameters of the fusion splicing, and the cleaning level of the office environment will all affect the value of the fusion splicing loss.

ZR Cable focuses on the research and development and sales of optical fiber communication products. Optical communication products include standard product optical cables, optical fiber jumpers Cables, mpo/mtp data centers, optical fiber distribution frames, etc., at ZR Cable you can buy all optical communication products in one stop.

You might be interested in

We use cookies to ensure that we give you the best experience on our website. By clicking on "Accept" or continuing to use this site, you agree to our use of cookies in accordance with our Cookie Policy .You can refuse the use of cookies here.

Accept