- Sales SupportContact Sales

- Call us at: +(86) 15211074652

- Send us a email at: info@zr-fibercable.com

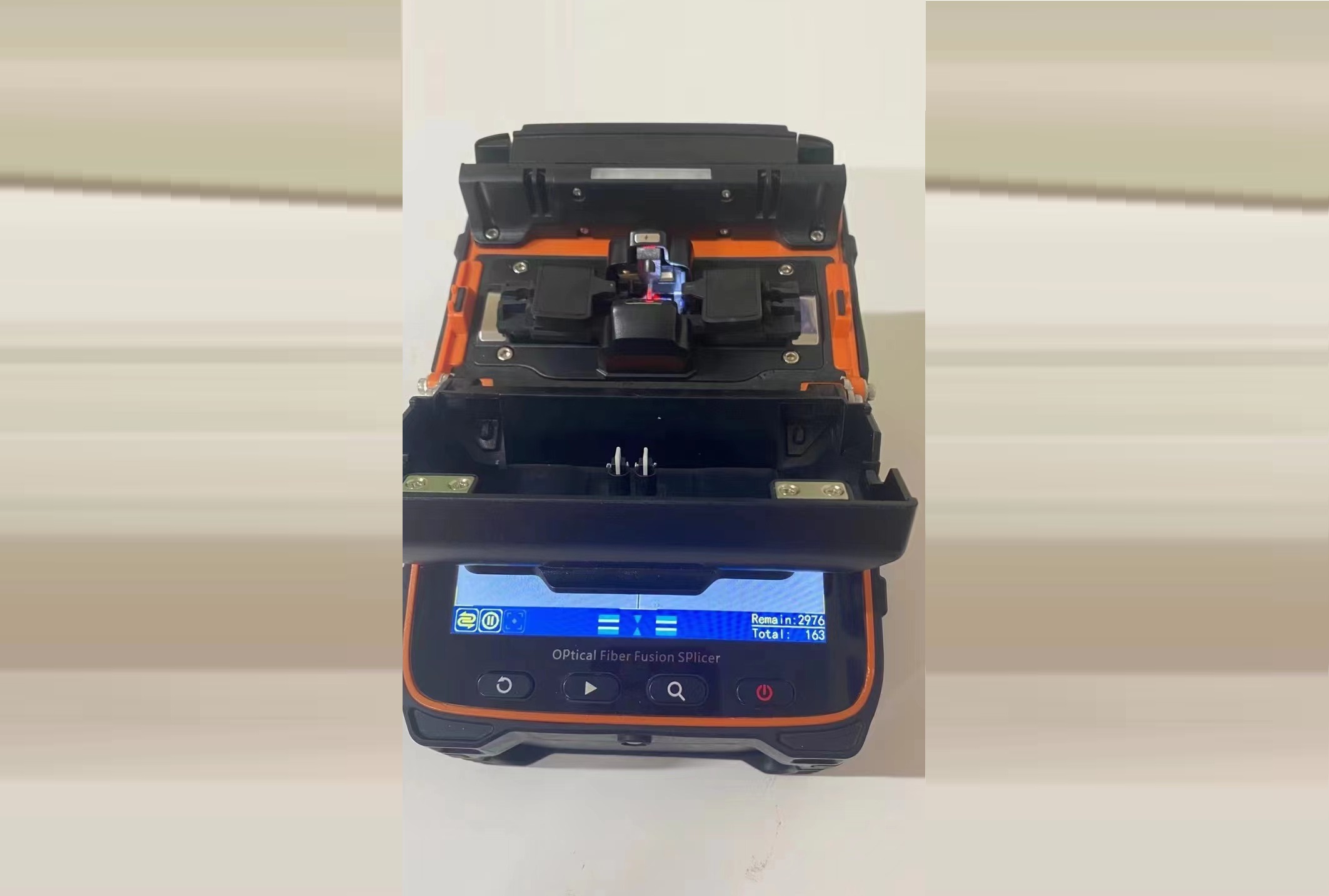

How to Choose the Right Fusion Splicer?

Fusion splicers play a crucial role in the installation and maintenance of fiber optic networks. They enable the permanent joining of optical fibers, ensuring low-loss and reliable connections. However, with numerous options available in the market, choosing the right fusion splicer can be a daunting task. In this article, we will provide you with a comprehensive guide on how to select the right fusion splicer for your specific needs.

Application and Usage:

Determine the intended application and frequency of use for the fusion splicer. Consider whether it will be used for long-haul backbone networks, local area networks, or occasional field installations. This will help you identify the required features and durability of the splicer.

Fiber Types and Compatibility:

Ensure that the fusion splicer supports the fiber types you are working with, such as single-mode or multimode fibers. Additionally, consider the compatibility with different fiber sizes (e.g., 250 µm, 900 µm, or ribbon fibers) and connector types (e.g., SC, LC, or MPO).

Splicing Capability:

Evaluate the splicer's performance in terms of splice loss, splice time, and alignment technology. Look for a fusion splicer with low splice loss, fast splice time, and advanced alignment techniques, such as core alignment or clad alignment, to ensure reliable and efficient splicing.

Splice Programs and Settings:

Check if the fusion splicer provides customizable splice programs and settings. This feature allows you to optimize splicing parameters based on the specific fibers and environmental conditions, ensuring consistent and high-quality splices.

II. Evaluate Technical Specifications:

Splice Loss and Performance:

Consider the splicer's advertised splice loss and performance capabilities. Look for splicers with low splice loss values, typically below 0.02 dB, to ensure minimal signal attenuation across spliced fibers.

Splice Time:

Splice time is an important factor, particularly when working on large-scale projects or in time-sensitive environments. Look for splicers that offer fast splice times, ideally below 10 seconds, to increase productivity and efficiency.

Arc Discharge Technology:

Fusion splicers use arc discharge technology to melt and fuse optical fibers. Evaluate the splicer's arc discharge technology, such as fixed or adjustable arc power, to ensure consistent and stable arcs for optimal splicing results.

Electrode Lifespan and Maintenance:

Check the electrode lifespan and maintenance requirements of the fusion splicer. Longer electrode lifespans reduce downtime and maintenance costs. Additionally, consider the availability and cost of replacement electrodes.

III. Consider User-Friendly Features:

Display and User Interface:

Evaluate the splicer's display and user interface. Look for splicers with clear, high-resolution displays that provide easy-to-understand splicing information. User-friendly interfaces with intuitive navigation and menu systems simplify operation and reduce training time.

Portability and Battery Life:

Consider the splicer's portability and battery life, especially if you require mobility for field installations. Look for lightweight and compact designs that are easy to transport. Longer battery life allows for extended use without frequent recharging.

Connectivity and Data Management:

Check if the splicer offers connectivity options, such as USB ports or Bluetooth, for data transfer and firmware upgrades. Some fusion splicers also provide software for data management and reporting, allowing you to track and organize splicing records efficiently.

IV. Assess Reliability and Support:

Manufacturer Reputation:

Research the reputation and track record of the fusion splicer manufacturer. Look for well-established companies known for producing reliable and high-quality splicers. Customer reviews and industry recommendations can provide valuable insights.

Warranty and Support:

Evaluate the warranty coverage and technical support provided by the manufacturer. A longer warranty period indicates the manufacturer's confidence in their product. Additionally, consider the availability of technical support, training, and access to firmware updates.

Calibration and Maintenance:

Check the calibration and maintenance requirements of the fusion splicer. Look for splicers that offer easy calibration procedures or self-calibration features to ensure accurate and consistent splicing results. Consider the availability and cost of maintenance services.

Choosing the right fusion splicer is a critical decision that directly impacts the quality and reliability of your fiber optic connections. By considering your requirements, evaluating technical specifications, assessing user-friendly features, and assessing reliability and support, you can make an informed choice. Remember to prioritize features such as compatibility, splice performance, usability, and manufacturer reputation. With the right fusion splicer in hand, you can ensure efficient and high-quality fiber optic splicing in your network installations and maintenance activities.

You might be interested in

We use cookies to ensure that we give you the best experience on our website. By clicking on "Accept" or continuing to use this site, you agree to our use of cookies in accordance with our Cookie Policy .You can refuse the use of cookies here.

Accept