- Sales SupportContact Sales

- Call us at: +(86) 15211074652

- Send us a email at: info@zr-fibercable.com

The quality and status assessment method of optical cable

Optical cables are widely used for long-distance communication, and their performance is critical for the success of the fiber optic system. Therefore, it is essential to assess the quality and status of the optical cable before and after installation. In this article, we will discuss the methods for assessing the quality and status of optical cables.

Visual Inspection

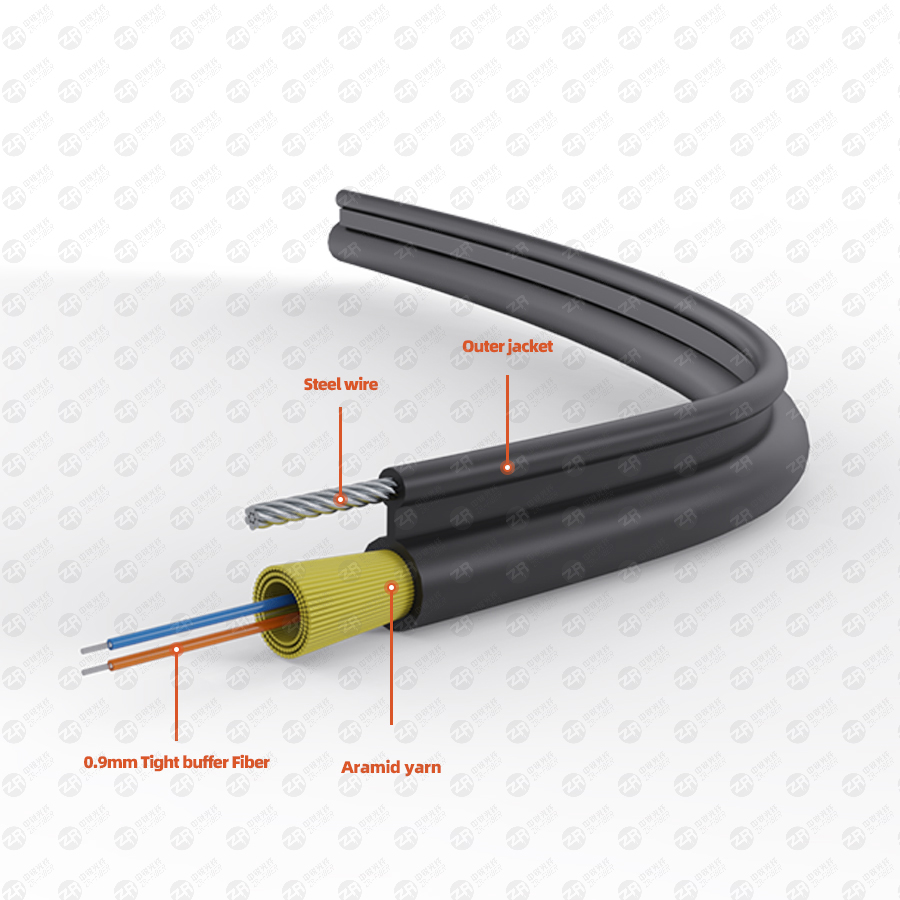

Visual inspection is the most basic and essential method for assessing the quality and status of optical cables. It involves a visual examination of the cable's exterior, including the jacket, sheath, and any connectors or splices. The purpose of visual inspection is to identify any visible damage or defects that may affect the cable's performance.

During visual inspection, the cable is inspected for signs of physical damage, such as cracks, nicks, or cuts, that may have occurred during transportation, storage, or installation. The connectors and splices are inspected for any signs of damage or misalignment that may affect the cable's optical performance.

Continuity Testing

Continuity testing is a method for verifying that the optical cable is intact and that there are no breaks or shorts in the fiber. Continuity testing is performed using an optical time-domain reflectometer (OTDR) or a light source and power meter.

The OTDR sends a pulse of light into the fiber and measures the amount of light that is reflected back to the instrument. The time delay between the pulse and the reflected light is used to calculate the distance to any breaks or faults in the fiber.

The light source and power meter are used to verify the continuity of the fiber by measuring the amount of light transmitted through the fiber and the power level of the light received at the other end of the cable.

Attenuation Testing

Attenuation testing is a method for measuring the loss of signal strength as the light travels through the fiber. Attenuation testing is performed using a light source and power meter.

The light source sends a known amount of light into the fiber, and the power meter measures the amount of light that is received at the other end of the cable. The difference between the transmitted and received power levels is used to calculate the attenuation, which is expressed in decibels (dB).

Attenuation testing is used to verify that the optical cable meets the specified attenuation requirements for the intended application.

Chromatic Dispersion Testing

Chromatic dispersion is a phenomenon that causes the different wavelengths of light to travel at different speeds through the fiber, resulting in a broadening of the light pulse. Chromatic dispersion testing is performed to verify that the optical cable can support high-speed data transmission.

Chromatic dispersion testing is performed using a specialized instrument called a dispersion analyzer. The analyzer sends a pulse of light into the fiber and measures the amount of dispersion in the signal.

Chromatic dispersion testing is used to verify that the optical cable meets the specified dispersion requirements for the intended application.

Polarization Mode Dispersion Testing

Polarization mode dispersion (PMD) is a phenomenon that causes the polarization of the light to change as it travels through the fiber, resulting in a broadening of the light pulse. PMD testing is performed to verify that the optical cable can support high-speed data transmission.

PMD testing is performed using a specialized instrument called a PMD analyzer. The analyzer sends a pulse of light into the fiber and measures the amount of PMD in the signal.

PMD testing is used to verify that the optical cable meets the specified PMD requirements for the intended application.

Conclusion

In conclusion, assessing the quality and status of optical cables is critical for ensuring the success of the fiber optic system. Visual inspection, continuity testing, attenuation testing, chromatic dispersion testing, and PMD testing are all methods for assessing the quality and status of optical cables.

You might be interested in

We use cookies to ensure that we give you the best experience on our website. By clicking on "Accept" or continuing to use this site, you agree to our use of cookies in accordance with our Cookie Policy .You can refuse the use of cookies here.

Accept