- Sales SupportContact Sales

- Call us at: +(86) 15211074652

- Send us a email at: info@zr-fibercable.com

How to reduce fiber splicing loss

When laying the optical cable, it must be laid according to the determined routing sequence, and ensure that the B end of the front cable is connected to the A end of the lower cable, so as to ensure that the connection can be spliced at the disconnection point and the fusion loss value is minimized.

Fiber optic cable installation is carried out as required. During the construction of optical cable laying, it is strictly forbidden to make small circles, fold and twist the optical cable. More than 80 people work on the 3-kilometer fiber optic cable, and more than 100 people work on the 4-kilometer fiber optic cable, equipped with 6-8 walkie-talkies; , the "optical cable shoulder" optical cable laying method can effectively prevent the occurrence of back buckling. The pulling force shall not exceed 80% of the allowable optical cable, and the maximum instantaneous pulling force shall not exceed 100%. The pulling force should be applied to the strength member of the optical cable. Optical cables should be laid in strict accordance with the requirements of optical cable construction to minimize the probability of optical fiber damage during cable construction and avoid increased fusion loss due to damage to the optical fiber core.

Choose experienced and well-trained fiber optic fusion personnel for fusion splicing. At present, most welding is performed automatically by welding machines, but the level of welding personnel directly affects the size of welding loss. Fusion splicing personnel should strictly follow the flow chart of the optical fiber fusion splicing process. During the splicing process, OTDR should be used to test the splice loss of the splice point during splicing. Those that do not meet the requirements must be reassembled. For points with a large splicing loss value, the number of repeated splicing should be 3~4 times.

Connecting cables should be done in a clean environment. It is strictly forbidden to work in the open air in a dusty and humid environment. The connection parts, tools and materials of optical cables should be kept clean. The cut fiber should not be exposed to the air for too long, especially in dusty and humid environments.

Use high-precision fiber end-face cutters to prepare fiber end-faces. The quality of the fiber end face directly affects the size of the splice loss. The cut optical fiber should have a flat mirror surface, no burrs, and no defects. The inclination angle of the fiber end face should be less than 1 degree. The high-precision fiber end face cutter not only improves the success rate of fiber cutting, but also improves the quality of fiber end face. This is especially important for splices that cannot pass OTDR testing (i.e. OTDR blind spots) and for fiber maintenance and repair.

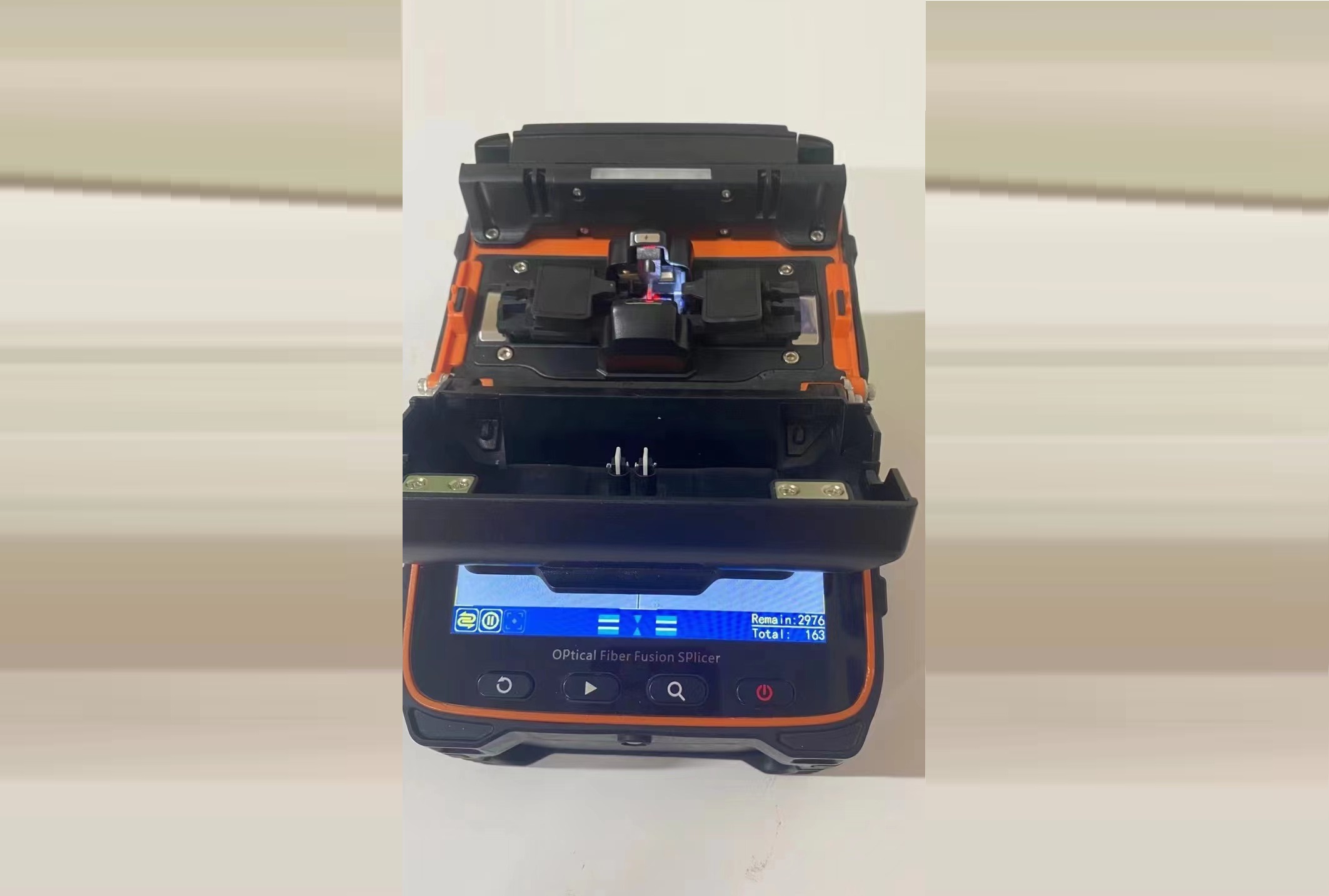

The fusion splicer should be used correctly. The function of the fusion splicer is to fuse two optical fibers together, so the correct use of the fusion splicer is also an important measure to reduce the loss of optical fiber fusion.

You might be interested in

We use cookies to ensure that we give you the best experience on our website. By clicking on "Accept" or continuing to use this site, you agree to our use of cookies in accordance with our Cookie Policy .You can refuse the use of cookies here.

Accept