- Sales SupportContact Sales

- Call us at: +(86) 15211074652

- Send us a email at: info@zr-fibercable.com

Fiber splicing

Fiber splicing

1. Preparation before fiber splicing

Before optical fiber fusion, first prepare the necessary operating equipment, tools and necessary materials, such as fiber strippers, knives, fusion splicers, heat shrinkable sleeves, alcohol cotton, etc., and check whether the power supply of the fusion splicer is sufficient and whether all materials are complete Wait, then remove the outer sheath and steel wire of the optical fiber and wait for the fiber segment to be fused, and find the corresponding optical fiber that needs to be fused.

2. Preparation of the end face

A qualified fiber end face is a necessary condition for fusion splicing, and the quality of the end face will directly affect the quality of fusion splicing. The preparation of the fiber end face includes three steps of stripping, cleaning and cutting.

1. Optical fiber stripping

2. Cleaning of bare fiber

3. Bare fiber cutting

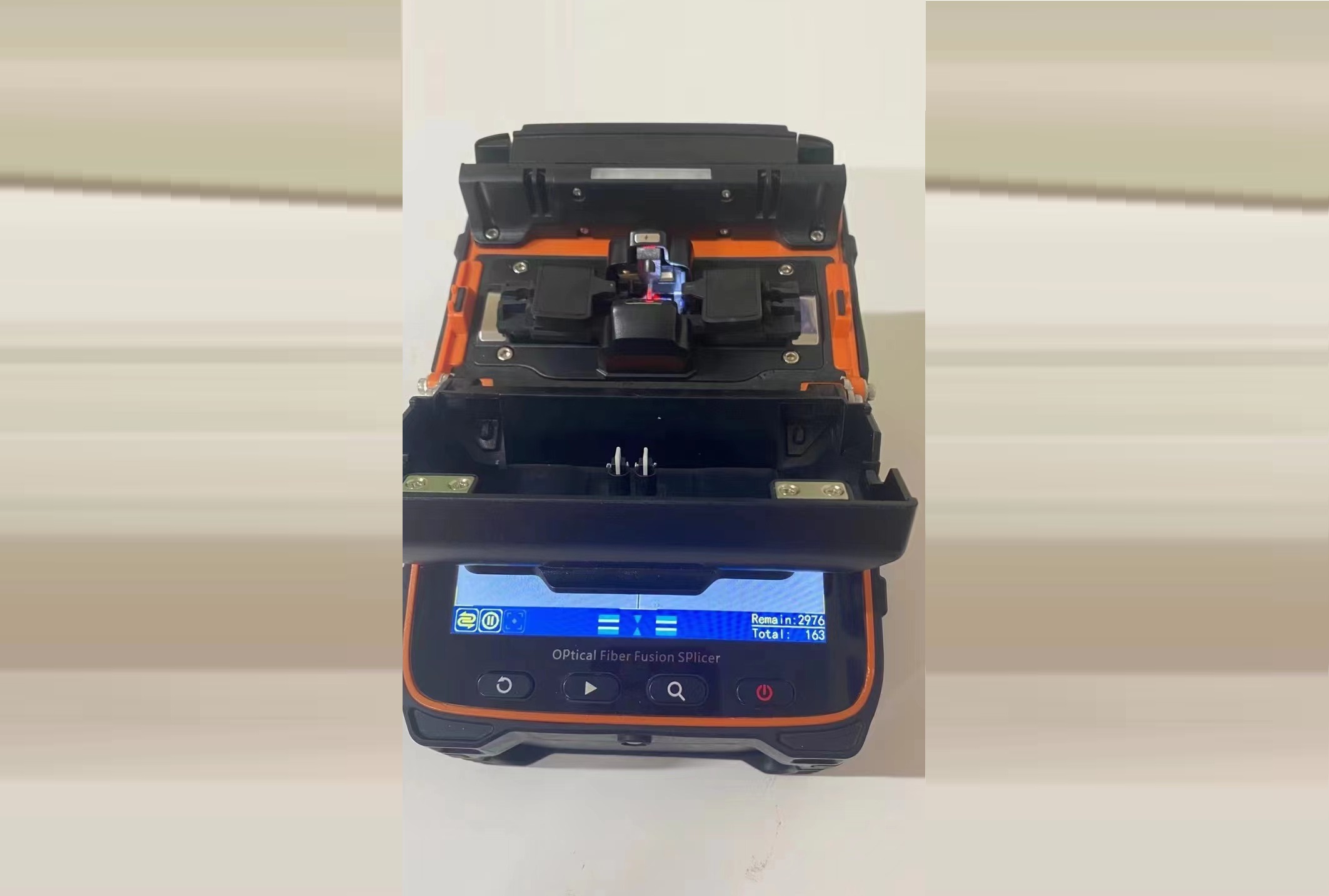

3. Fiber splicing

Fusion optical fiber should be equipped with suitable battery capacity and precision fusion splicing equipment, that is, fusion splicer, according to the requirements of optical cable engineering. Since the fusion splicer is a high-tech, high-precision equipment, and the price is relatively high, the selected fusion splicer should have excellent performance, stable operation, high welding quality, and be equipped with a dustproof windshield and a large-capacity battery. ., Applicable to various optical cable projects (some fusion splicers are small in size, easy to operate, equipped with a simple cutter, the battery and the host are combined into one, easy to carry, especially suitable for small and medium-sized optical cable projects).

4. Fiber finishing

Fiber optic coiled. The scientific optical fiber coiling method can not only avoid the breakage of optical fiber caused by extrusion, but also has reasonable optical fiber layout, small additional loss, can stand the test of time and harsh environment, and is conducive to future inspection and maintenance.

When the optical fiber is coiled, it is generally carried out in units along the branching direction of the loose tube or optical cable. One or more optical fibers in the loose tube, or the optical fibers in the branch direction optical fiber, after each fusion splicing heat shrink, wrap the fiber once to avoid loose fiber. The chaos of optical fibers between the sleeves or between different branch optical cables makes it suitable for layout, easy installation, easy disassembly, and easy maintenance. It is also possible to reserve heat-shrinkable tube placement units in the tray, take the fiber as the unit, and place the number of heat-shrinkable tubes according to the small area of the reserved tray in the fusion splice box, thus avoiding the same problem caused by different placement positions. The fiber bundles are uneven, difficult to wind and fix, and even sharp bends and small circles appear.

5. Optical cable connection quality inspection

During the entire fusion splicing process, OTDR testing instruments should be used to strengthen monitoring to ensure the quality of optical fiber fusion, reduce the additional loss caused by coiled optical fibers and the possible damage to optical fibers caused by sealing boxes. Absolutely can not judge with the naked eye. bad:

(1) Real-time tracking and monitoring of each core fiber during the fusion splicing process to check the quality of each splicing point;

(2) After each coiled fiber, conduct a routine inspection of the coiled fiber to determine the additional loss caused by the coiled fiber;

(3) Before sealing the fusion splice box, uniformly measure whether there is any leakage of all optical fibers, and whether the reserved space for optical fibers squeezes optical fibers and connectors;

(4) After sealing the box, carry out final monitoring on all optical fibers to check whether the box causes damage to the optical fiber.

You might be interested in

We use cookies to ensure that we give you the best experience on our website. By clicking on "Accept" or continuing to use this site, you agree to our use of cookies in accordance with our Cookie Policy .You can refuse the use of cookies here.

Accept