- Sales SupportContact Sales

- Call us at: +(86) 15211074652

- Send us a email at: info@zr-fibercable.com

Analysis of Optical Fiber Splicing Technology

Regarding splicing for fiber type applications, the standard definition of fiber splicing is joining two fibers together. Another, more common method of joining optical fibers is called termination or splicing. Splicing is the most common method used in this field and has been applied in fiber optic assembly plants. In field installations, splicing is a faster and more efficient method for recovering fiber when a buried fiber is accidentally severed.

splicing type

There are two methods of splicing, mechanical or fusion. Both methods have much lower insertion loss than fiber optic connectors.

mechanical splicing

Mechanical fiber splicing is an alternative splicing technique that does not require a fusion splicer. A mechanical splice is the junction of two or more optical fibers that are aligned and held in place by a component that uses an index-matching fluid to align the fibers. Mechanical splices use small mechanical splices, about 6 cm long and 1 cm in diameter, to permanently join two optical fibers together. This precisely aligns the two bare fibers, which are then mechanically secured.

Snap-on caps, adhesive caps, or both are used to secure the joint permanently. The optical fibers are not permanently connected together, but are only held together precisely so that light can pass from one to the other. (insertion loss<0.5dB)

Splice loss is typically 0.3dB. However, mechanical fiber splicing has a higher reflectivity than fusion splicing methods. Fiber optic mechanical splices are small and easy to use, making them convenient for quick repairs or permanent installations. They come in permanent and reentrant types. Fiber optic mechanical splices are available for singlemode or multimode fiber.

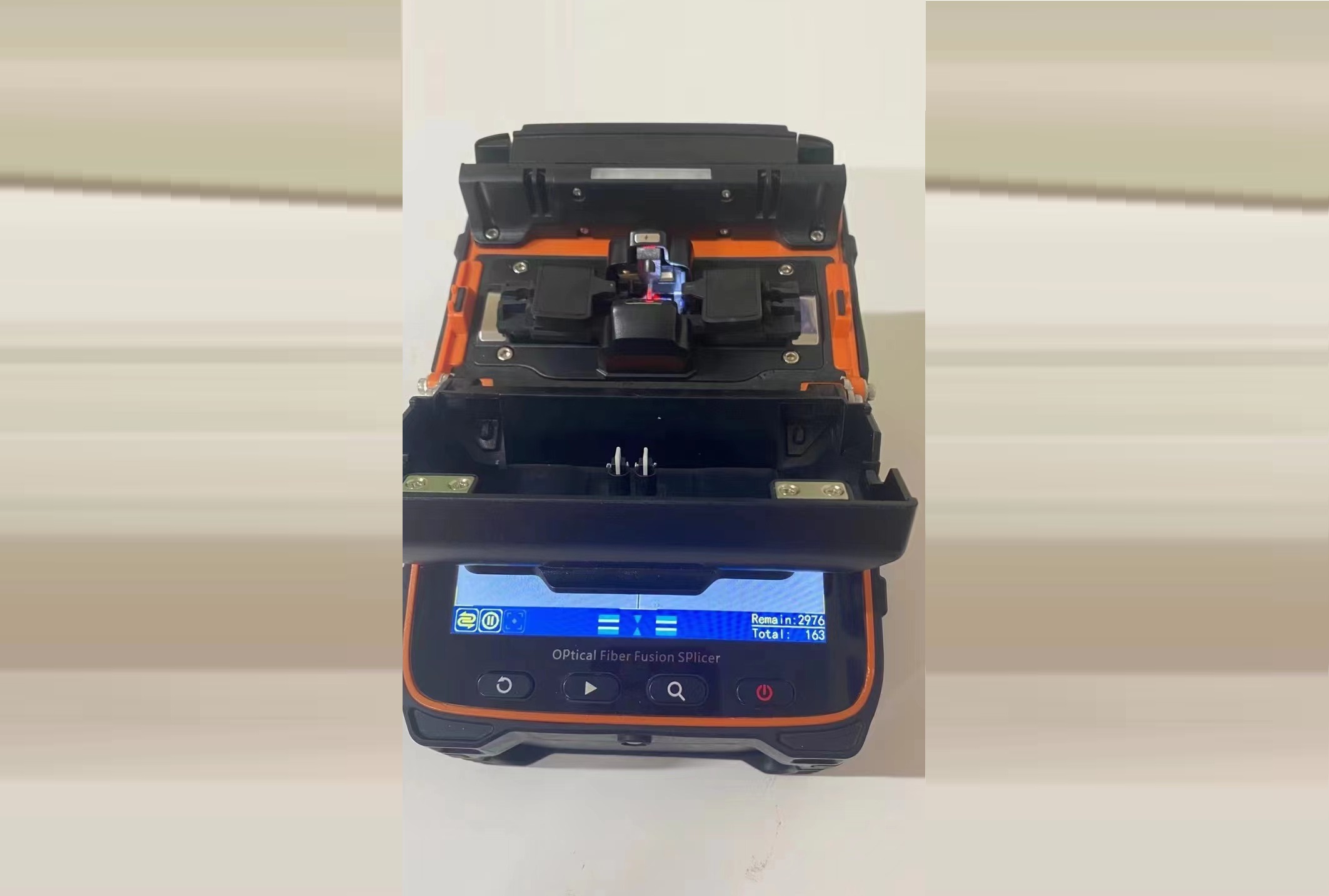

Fiber Fusion Splicer

welding

Fusion splicing is more expensive than mechanical splicing, but lasts longer. The fusion method fuses the fiber cores together with less attenuation. (insertion loss<0.1dB)

During fusion splicing, the two fiber ends are precisely aligned using a specialized fusion splicer, and then an electric arc or some type of heat is used to "fuse" or "weld" the glass ends together. This creates a transparent, non-reflective and continuous connection between fibers, allowing very low light loss propagation. (Typical loss: 0.1 dB)

The fusion splicer performs fiber splicing in two steps.

Precise Alignment of Two Fibers

Creates a small electric arc to melt the fibers and weld them together

With proper training, fiber splicing technicians can typically splice singlemode and multimode fibers with insertion loss less than 0.1dB.

In addition to the typical lower splice loss of 0.1dB, the advantages of fusion splicing include less back reflections.

A common application for splicing is splicing in longer lengths of fiber outside the factory. Here, multiple optical fibers are required for an entire length of wire. Splicing is commonly used to terminate single-mode fibers (by splicing pre-terminated pigtails to each fiber), but there are other uses as well. It is important to note that slicing can be used to mix different types of fibers, for example connecting 48 fibers to 6 8 fibers going to different places.

You might be interested in

We use cookies to ensure that we give you the best experience on our website. By clicking on "Accept" or continuing to use this site, you agree to our use of cookies in accordance with our Cookie Policy .You can refuse the use of cookies here.

Accept